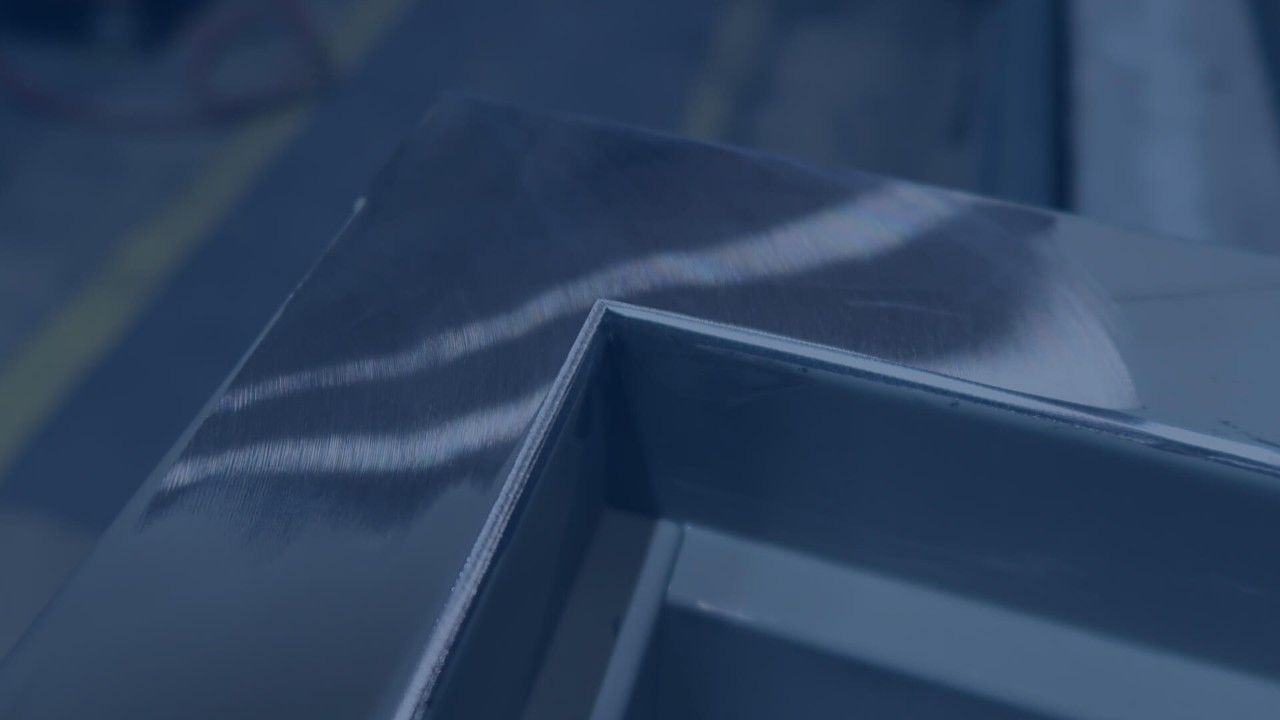

The FS, KS & MS Series three-sided stainless steel frames are engineered to meet the architectural requirements for stainless steel doors and frames in building applications requiring exceptional sterile, corrosion resistance and design appearance.

FEATURES AND BENEFITS

Strength, durability and ease of installation

- Attractive, tight and closed die-mitered corner connection; miter includes four corner tabs designed with concealed connection, eliminating the need for continuous profile welding

- Factory prepared for field-installed silencers

- 100% stainless steel components ensure against rust, inside and out

- Finish Options

- #2B - Smooth, rolled mill finish smooth and unpolished for tunnels or "back of house" applications typically painted

- #4 Brushed Satin - Polished with one directional grain, a popular stainless aesthetic

Typical applications

Frames built with stainless steel are often specified in high-end performance and architectural openings such as:

- Industries that require sterile environments such as hospitals, labs, pharmaceutical, or food

- Architectural entrances

- Corrosive environments exposed to exterior elements or harsh chemicals

Series Profiles

FS Flush Series

Installed into existing masonry with EMA anchors, or into new masonry or stud walls as part of the wall framing sequence, FS Flush Series may be specified and supplied as KD (knock-down) for field assembly prior to installation or welded for installation as a complete unit. Adjustable base anchors allow for attachment directly to the wall sill runner and facilitate installation adjustment when the floor is not level

KS Drywall Series

Installed into the finished wall as KD (knock-down) only. Sill attachment is made through the frame face, directly into the wall sill runner; bottom of frame face is supplied with factory countersunk holes for screw attachment

MS Multi-use Series

A hybrid of FS and KS Series frames, MS Series is typically used in stud walls as part of the wall framing sequence and can be supplied as KD (knock-down) or welded similar to FS Series flush frames, but provides backbend returns similar to KS Series drywall frames so that drywall can more easily slide into place between the stud wall and steel frame. Also like KS Series, the sill attachment is made through the frame face, directly into the wall sill runner; bottom of frame face is supplied with factory countersunk holes for screw attachment

Exceeds industry standards

- Overall frame construction exceeds ANSI A250.8-2017 (SDI-100), the standard set by SDI specifying sizes, design, materials, construction, finishing and performance for standard commercial steel doors and frames

- Exceptional corrosion resistance, conforming to ASTM A666:

- Type 304 Alloy: typical corrosion resistance

- Type 316 Alloy: heavy duty corrosion resistance

- Sound-rated door and frame assemblies up to STC 46 on Singles and 43 on Pairs, seals not included

- Hurricane approved (NOA Miami-Dade County Florida)

- Frames meet fire rating requirements; they are listed for installations requiring compliance to both neutral pressure testing (ASTM E152 and UL-10B) and positive pressure standards (UL-10C)

Technical Data Guide

For more complete information on FS, KS & MS Series Frames, download the Steelcraft Technical Data Manual.

- FS, KS, & MS Series (Pages 222-227): Includes Anchors, Hardware Preps, Lights, Fire Ratings