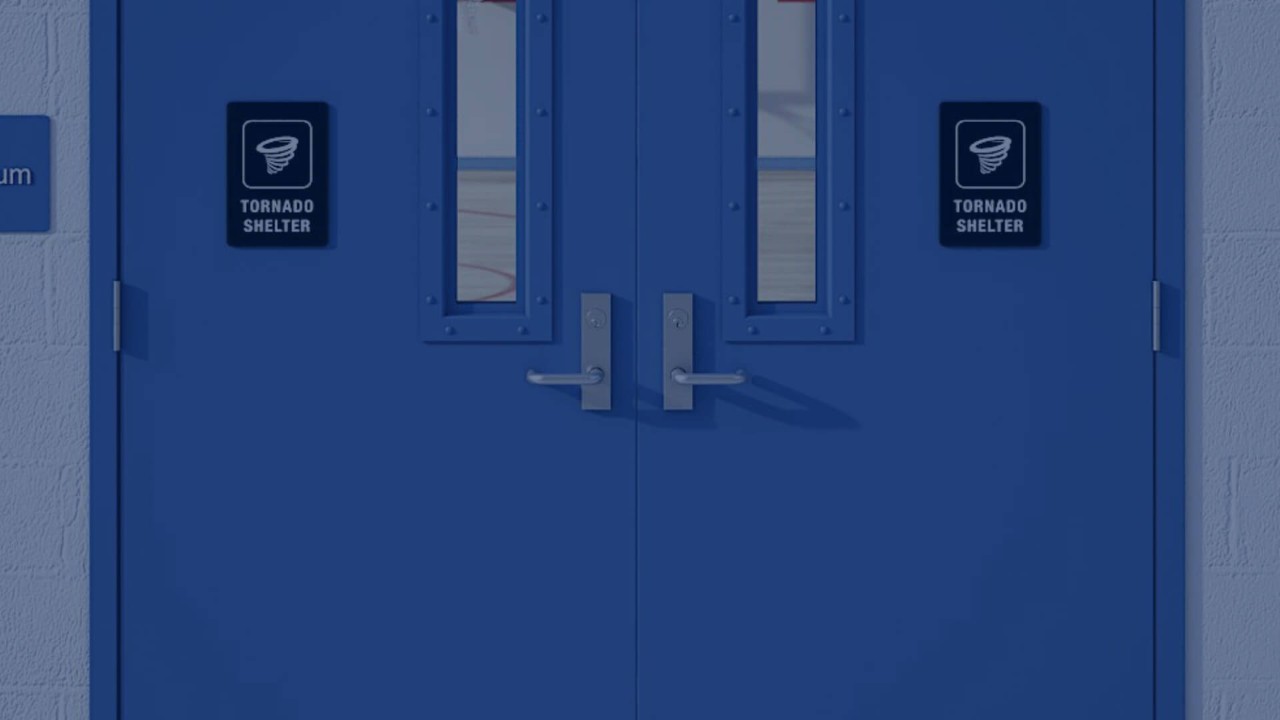

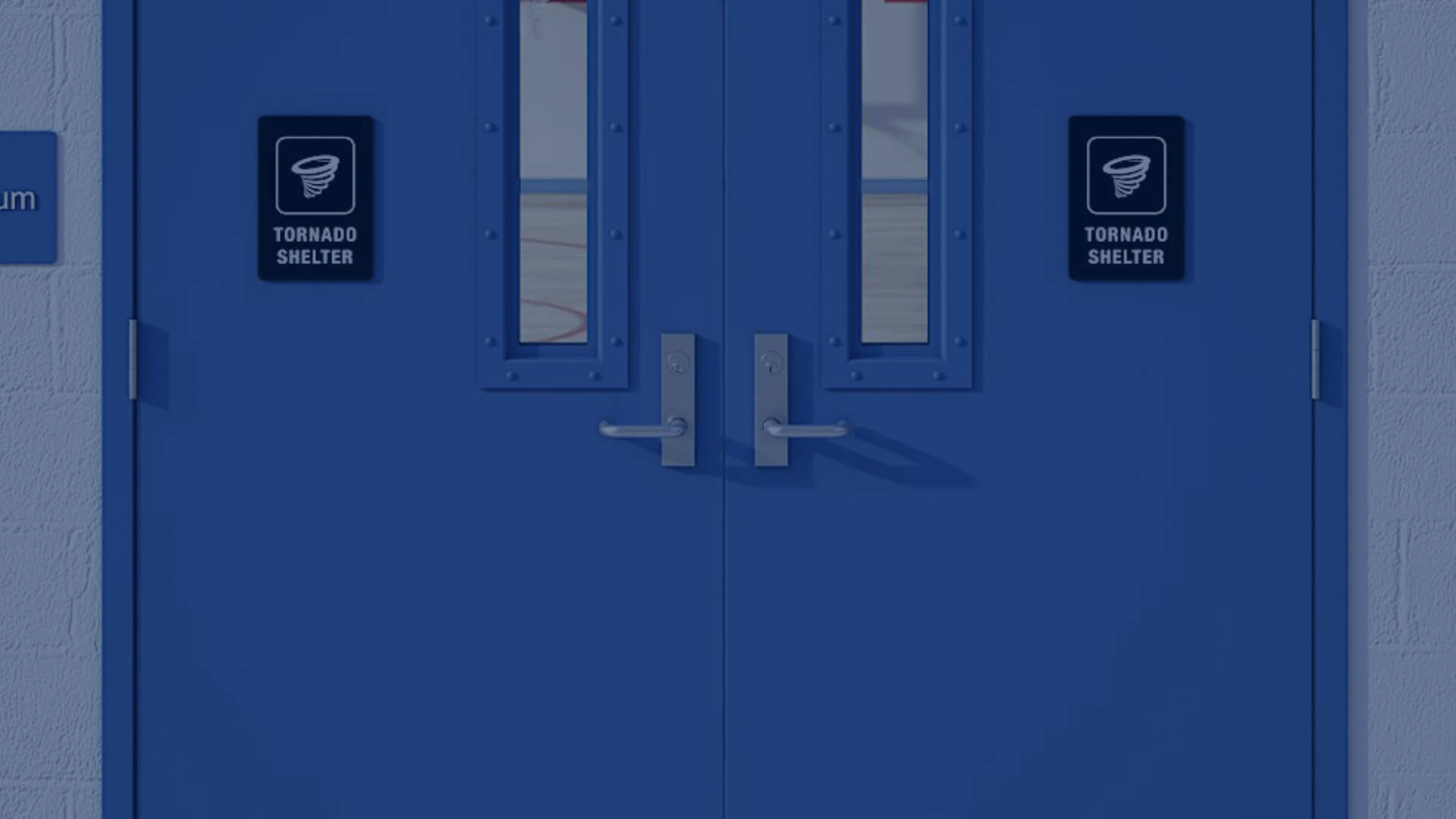

The PW14 Paladin™ Door System is designed and tested to withstand extreme effects of wind and flying debris. It is ideal for commercial applications in tornado alley, residential shelters, and school gymnasiums constructed as tornado shelters in K12 and university facilities.

Paladin Door Systems have been assembly tested and certified with Allegion hardware. They are labeled from the factory showing compliance with ICC 500-2020, FEMA P-320 (2021), and FEMA P-361 (2021) as required by the International Building Code.

FEATURES & BENEFITS

- Superior Performance

- Steel stiffened core

- Galvanized steel for superior strength and resistance to corrosion

- Beveled hinge and lock side edges ensure easy, smooth operation

- Seamless full height, epoxy filled mechanical interlock edges provide structural support and stability the full height of the door

- Heavy gauge reinforcement

- Simple Install

- Patented universal hinge preparations allow for easy field conversion from standard to heavy weight hinges

- Adjustable base anchors for unlevel floor installs

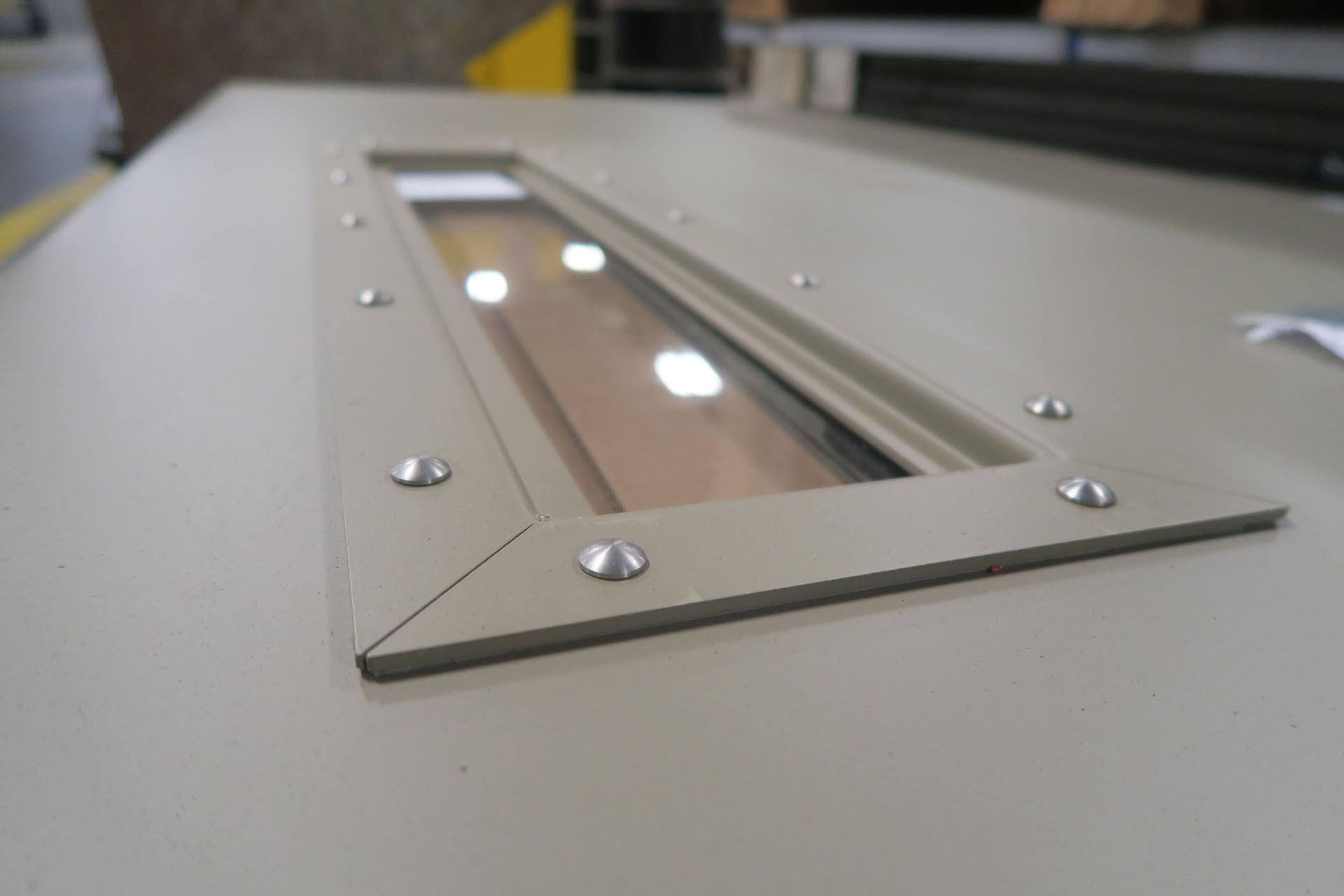

- Lights for visibility & aesthetics

- Factory installed Glass Light Kits

- ADA compliant

- Available as rated and non-rated

- Supplied by TGP

- Can be added to any Steelcraft approved 3-sided opening

TORNADO ASSEMBLIES

Certified Tornado assemblies include a Paladin Door & Frame with Schlage LM9300 Levers or Von Duprin WS-T Exit Devices as latching hardware. Various configurations are available across the Allegion portfolio of brands including Glynn-Johnson, Ives, LCN, TGP, and Zero.

Review the Steelcraft Tech Data Manual & customer bulletin for detail on latest ICC500 label availability.

Meeting & Exceeding Industry Standards

- Steelcraft is SDI Certified through regular audits to ensure manufacturing, performance and quality standards set by the Steel Door Institute

- To learn more about SDI standards and membership requirements, visit SDI’s website

- Listed for installations requiring compliance to both neutral pressure testing (ASTM E152 and UL-10B) and positive pressure standards (UL-10C)

- Factory-applied baked-on rust inhibiting primer meets ANSI A250.10-2011

- Listed and labeled by Intertek and UL showing compliance with ICC500-2014, ICC 500-2020 and and FEMA 320/361.